ENAG, creative energy of a manufacturer

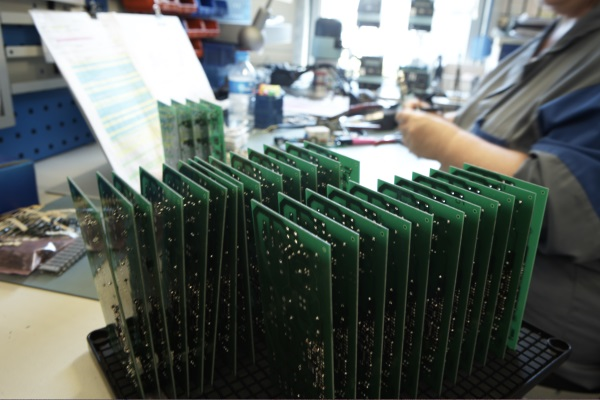

ENAG design, develop and manufacture energy conversion systems working in rugged environments for over 70 years. Our expertise in static and dynamic energy conversion is based on the most reliable technologies of power electronics and electro mechanics. Major international companies acknowledge our capability of providing first class service and products, both standard and customized, for intensive use in rugged environments. Used in the Marine, Offshore, MRE (Marine Renewable Energies), defence, Railway and Industrial markets our products are renowned for their quality and reliability.